The mechanical seal consists of a static ring, a dynamic ring, a compensating buffer mechanism, an auxiliary sealing ring, and a transmission mechanism. The end faces of the static and dynamic rings are perpendicular to the axis of the pump and closely adhere to each other, forming a rotating sealing surface. The static ring and gland, as well as the dynamic ring and shaft, are sealed with auxiliary sealing rings to compensate for the buffering mechanism's action in driving the sealing ring to move along the axial direction of the pump, keeping the end faces of the dynamic and static rings in contact, and compensating for the wear of the sealing ring end faces.

Main characteristic parameters of 01 mechanical seal

1. Shaft diameter: The shaft diameter range of pump mechanical seals is generally 6~200mm, and special ones can reach 400mm. The shaft diameter of the pump is usually determined by strength requirements, and it is rounded or modulated with a shaft sleeve to meet the standard shaft diameter of mechanical seals.

2. Speed: It is generally the same as the speed of the pump, and the speed of a centrifugal pump is generally ≤ 3000r/min; High speed centrifugal pump ≤ 8000r/min; Special pump ≤ 4000r/min.

3. Average circumferential velocity of sealing surface: refers to the circumferential velocity of the average diameter of the sealing end face. The average linear speed of the sealing surface has a significant impact on the heating and wear of the sealing surface (i.e. friction pair). The circumferential velocity of general mechanical seals is ≤ 30m/s; The circumferential velocity of the application of spring stationary mechanical seals is ≤ 100m/s; Special up to ≤ 150m/s.

4. End face specific pressure: The end face specific pressure pc is the contact pressure (MPa) borne on the sealing surface. The specific pressure of the end face of the end face seal should be controlled within a reasonable range. If it is too small, it will reduce the sealing performance, while if it is too small, it will exacerbate the heating and wear of the sealing surface. Reasonable end face specific pressure value for mechanical seals used in pumps; Internal mechanical seal, generally taken as pc=0.3~0.6MPa; For external installation, take pc=0.15~0.4MPa. When the lubrication is good, the end face specific pressure can be appropriately increased. For liquids with high viscosity, the end face specific pressure should be increased, which can be taken as pc=0.5~0.7MPa; For liquids that are volatile and have poor lubrication, a smaller end face specific pressure should be taken, which can be taken as pc=0.3~0.45MPa.

Assembly Procedure for 02 Mechanical Seals

The structure and assembly methods of mechanical seals vary. However, almost all mechanical seals require two major steps: pre assembly and final assembly.

1. Pre assembly: It refers to assembling parts into transmission components and stationary components. Install the sealing ring of the moving ring into the inner hole of the moving ring to form the moving ring assembly. Install the spring and push ring on the spring seat in sequence, screw the transmission screw into the push ring, adjust the pre compression amount of the spring, and form a compensation buffer mechanism. Align the pin and install the moving ring component into the compensation buffer mechanism to form the transmission component.

Install the static ring seal onto the static ring, fit it into the static ring seal chamber, and evenly press the cover to form a static component.

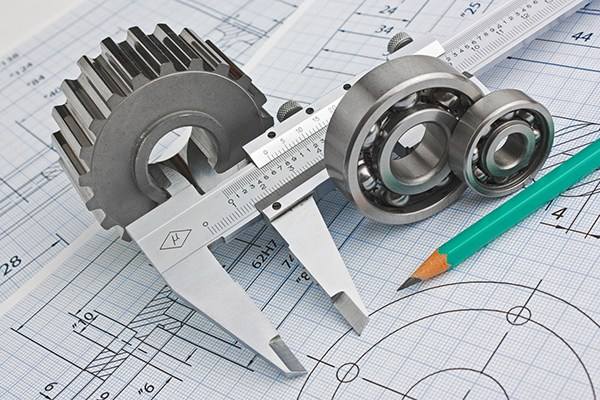

2. General assembly: Install the transmission components and stationary components into the shaft and sealing chamber, and complete the assembly of the mechanical seal. Measure the distance from the sealing end face of the dynamic ring to the sealing chamber end face and the distance from the sealing end face of the static ring to the end cover end face using a depth vernier caliper. The actual compression amount of the mechanical seal is also the specific pressure, which can be adjusted appropriately in actual work.

Excessive compression of mechanical seal springs affects the service life of the mechanical seal, while mechanical seals are prone to leakage.